The Indian steel market has witnessed a remarkable journey of growth and evolution, reflecting the country’s industrial prowess and economic development. From its humble beginnings in the late 19th century to emerging as one of the world’s leading steel producers, India’s steel sector has traversed a path marked by innovation, challenges, and strategic interventions. Understanding this trajectory requires a closer look at key milestones and global economic trends that have shaped the Indian steel market.

Understanding the Indian Steel Market From its Inception:

- 1875: The journey of the Indian steel industry can be traced back to the establishment of the Bengal Iron and Steel Company in Barakar. This marked the nascent phase of steel production, driven by colonial economic imperatives and the budding industrialisation process.

- 1907: A pivotal moment arrived with the establishment of the Tata Iron and Steel Company (TISCO) in Jamshedpur. Founded by visionary industrialist Jamsetji Tata, TISCO laid the foundation for modern steelmaking in India. It played a crucial role in the country’s industrial development.

- 1937: The Steel Corporation of Bengal was established, further expanding the steel manufacturing landscape in India. During this time, the sector experienced gradual growth while operating under colonial rule in a constrained economic environment.

- 1954: Hindustan Steel Limited (HSL) was set up, representing a significant step towards self-reliance in steel production. The establishment of HSL marked the beginning of state-led initiatives to bolster the steel industry and reduce dependence on imports.

- 1973: A watershed moment occurred with the presentation of a new model for managing the steel industry to the Indian Parliament. This led to the formation of the Steel Authority of India Limited (SAIL), a state-owned enterprise tasked with overseeing major steel plants.

- 1991: The Government of India initiated liberalisation measures, signalling a shift towards market-oriented policies. The iron and steel industries were removed from the reserved list as part of this process. This opened up avenues for private investment and fostered competition.

- 2005: India achieved a significant milestone by emerging as one of the top 10 steel producers globally. This underscored the country’s growing stature in the international steel market. It highlighted its potential for further expansion and modernisation.

- 2018: India cemented its position as a major player in the global steel industry by becoming the second-largest producer of crude steel. This achievement underscored the resilience and competitiveness of the Indian steel sector in the face of evolving market dynamics and technological advancements.

Global Economic Trends Impacting the Indian Steel Market:

The evolution of the Indian steel market has been intricately linked to global economic trends and geopolitical shifts. Several key factors have exerted influence on the trajectory of the Indian steel plants:

- Globalisation and Trade Liberalisation: The process of globalisation has facilitated the integration of Indian steel producers into the global market. It has enabled access to new technologies, markets, and capital. Trade liberalisation measures have also opened up avenues for export-oriented growth, enabling steel plants to tap into international demand.

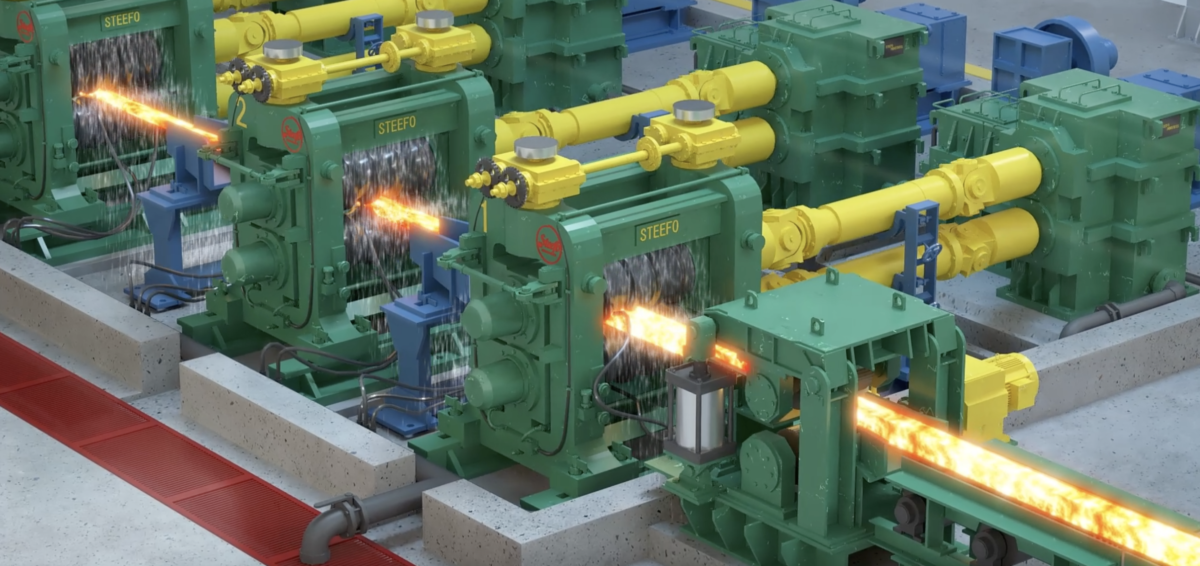

- Technological Advancements: Rapid technological innovations have transformed the steel industry, leading to increased efficiency, productivity, and sustainability. The adoption of advanced processes such as electric arc furnaces, continuous casting, and automation has enhanced the competitiveness.

- Shifts in Global Demand: Changing consumption patterns, urbanisation trends, and infrastructure development have influenced global steel demand. Emerging economies have emerged as key drivers of steel consumption, presenting opportunities for Indian steel producers to cater to growing market segments.

- Resource Constraints and Environmental Pressures: Challenges related to raw material availability, energy consumption, and sustainability have shaped the strategic priorities of steel companies. Efforts to diversify sourcing, optimise resource utilisation, and adopt cleaner technologies reflect a broader commitment to sustainable development.

Technological Advancements and Innovation:

Technological advancements have been instrumental in shaping the trajectory of the Indian steel market, enabling manufacturers to enhance efficiency, quality, and sustainability. Here are key points highlighting the impact of these innovations:

- IoT Enabled by AI: The convergence of IoT and AI has ushered in a new era of smart manufacturing in the steel industry. IoT sensors embedded throughout the production process collect real-time data on temperature, pressure, vibration, and other crucial parameters. AI algorithms analyse this data to optimise operations, predict maintenance needs, and minimise downtime, improving overall efficiency and productivity.

- Robotics: Robotics plays a pivotal role in automating repetitive and labour-intensive tasks in steel plants. Robotic arms equipped with advanced sensors and actuators perform tasks such as material handling, welding, and quality inspection with precision and consistency. By reducing reliance on manual labour and enhancing process efficiency, robotics contribute to cost savings and operational excellence.

- Drones: Drones have emerged as valuable tools for monitoring and managing various aspects of steel production facilities. Equipped with high-resolution cameras and sensors, drones conduct aerial surveys of plant infrastructure. They also identify potential safety hazards and facilitate maintenance inspections in hard-to-reach areas. The use of drones enhances safety, reduces inspection times, and enables proactive maintenance planning.

Sustainability and Environmental Regulations:

Steel manufacturers are increasingly adopting sustainable practices and technologies to mitigate environmental impacts and enhance long-term viability. Here are key considerations regarding sustainability and environmental regulations in the Indian steel market:

- Resource Efficiency: Steel plant manufacturers are focusing on optimising resource utilisation and minimising waste generation throughout the production process. Advanced technologies such as scrap recycling, energy-efficient furnaces, and water recycling systems enable companies to reduce raw material consumption. This also helps conserve energy and lower carbon emissions.

- Environmental Regulations: Stringent environmental regulations impose emission limits, wastewater discharge standards, and waste management requirements on steel manufacturers. Compliance with these regulations necessitates investments in pollution control equipment, emission monitoring systems, and environmental management systems. Proactive adherence to environmental standards not only ensures regulatory compliance but also enhances corporate reputation and stakeholder trust.

- Carbon Footprint Reduction: Mitigating greenhouse gas emissions is a priority for the Indian steel industry, given its significant contribution to carbon dioxide emissions. Steel producers are investigating low-carbon methods to decarbonise their production process and reduce environmental impact. These methods include hydrogen-based steelmaking, carbon capture and storage, and integration of renewable energy. Collaboration with government agencies, research institutions, and industry stakeholders is essential to accelerate the transition towards a low-carbon future.

- Circular Economy Initiatives: Embracing the principles of the circular economy, steel plant manufacturers are implementing strategies to close the loop on material flows and minimise waste generation. Initiatives such as product lifecycle assessments and resource recovery from by-products promote resource conservation and foster a more sustainable value chain.

Market Challenges and Opportunities:

Challenges:

Global Economic Uncertainties: The steel industry is highly sensitive to global economic conditions, including trade tensions, geopolitical conflicts, and currency fluctuations. Uncertainties in global markets can impact steel prices, demand-supply dynamics, and investment sentiments, posing challenges for manufacturers.

Raw Material Procurement: Securing a cost-effective supply of raw materials, such as iron ore, coal, and scrap metal, remains a significant challenge. Dependency on imports, volatile commodity prices, and logistical constraints can disrupt production schedules and affect profitability.

Technological Disruptions: Technological advancements offer opportunities for efficiency gains and product innovation. But they also present challenges in terms of capital investment, workforce upskilling, and cybersecurity risks. Adapting to rapidly evolving technologies requires strategic planning and continuous investment in research and development.

Global Competition: The Indian steel industry faces intense competition from domestic players as well as international giants in the global market. Competing on price, quality, and innovation requires continuous improvement in productivity, supply chain efficiency, and customer service.

Opportunities:

Infrastructure Development: India’s ambitious infrastructure development plans, including investments in transportation and renewable energy projects, present significant opportunities for steel manufacturers. Rising demand for steel-intensive infrastructure projects creates a conducive environment for market expansion and revenue growth.

Government Initiatives: Governmental policies and initiatives aim to promote domestic manufacturing, increase exports, and improve the ease of doing business. These policies create a regulatory environment that is favourable for the steel industry.

Speciality Steel Production: The focus on producing high-value speciality steel for strategic sectors such as defence, automotive, and aerospace presents lucrative opportunities for steel plants. Leveraging technological capabilities and market expertise can enable companies to capture niche markets and achieve premium pricing.

Export Potential: India’s competitive advantage in terms of skilled labour, cost-effective production, and proximity to key export markets positions it as a prominent player in the global steel trade. Exploring export opportunities in neighbouring countries and emerging markets can diversify revenue streams and mitigate domestic market risks.

Research and Innovation: Investing in research and innovation initiatives facilitates product differentiation, process optimisation, and sustainability improvements in the steel industry. Collaboration with research institutions and technology partners enhances competitiveness and drives long-term value creation.

Government Policies/Initiatives and Industry Support:

Here are notable government policies and initiatives contributing to the development:

- Production-linked Incentive (PLI) Scheme for Specialty Steel: In July 2021, the Union Cabinet approved the PLI scheme for speciality steel. It was consented with an investment target of approximately Rs. 400 billion (US$ 5.37 billion). The scheme aims to expand speciality steel capacity, attract investments, and promote domestic manufacturing in critical segments.

- Mission Purvodaya: Launched in 2020, Mission Purvodaya seeks to accelerate the development of eastern India into an integrated steel hub. This initiative aims to harness the region’s rich mineral resources, infrastructure potential, and skilled workforce to drive industrial growth and economic development.

- Hydrogen Commercialisation in the Steel Sector: In June 2021, JSW Steel, CSIR-National Chemical Lab, Scottish Development International, and India H2 Alliance entered a collaboration. This initiative aims to explore hydrogen-based technologies for decarbonising steel production and reducing environmental impact.

- Investment Allocation in Union Budget: The Union Budget allocates significant resources to the Ministry of Steel to support infrastructure development, research, and capacity expansion. Investments in critical transport infrastructure projects and technology-driven initiatives strengthen the industry’s competitiveness and resilience.

- Trade Policies and Import Duties: The government has implemented measures such as raising import duties and imposing anti-dumping duties to protect domestic steel producers from unfair trade practices. These policy interventions aim to ensure a level playing field and promote a conducive environment for domestic manufacturing.

The Future of the Indian Steel Market From a Global Perspective:

The future of the Indian steel market on a global scale is poised for significant advancements driven by sustainability, technological innovations, and strategic integration. With a steadfast commitment to reducing carbon emissions and embracing eco-friendly production processes, India’s steel industry is set to witness sustainable growth. The adoption of advanced technologies will enhance operational efficiency and pave the path for Industry 4.0 transformation. This will foster a new era of smart manufacturing.

India’s integration into global value chains and policies supporting exports will solidify its position as a supplier of high-quality steel products. Indian steel plants’ future depends on specialized steel grades, innovation, and collaboration with stakeholders. These factors will ensure the market’s competitiveness and resilience in the global arena.