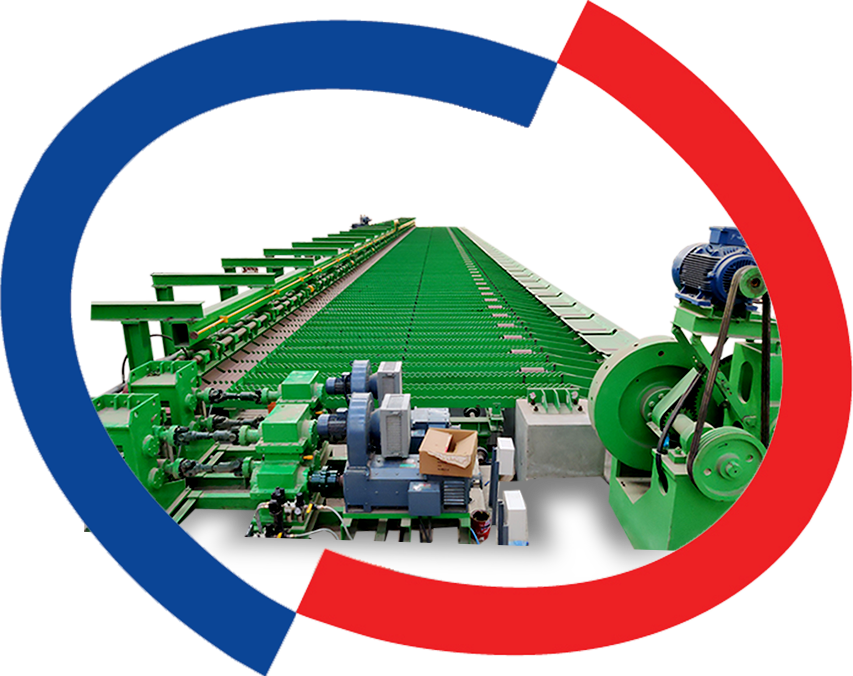

Automatic Cooling Beds

Automatic Cooling beds are used to cool down TMT Bar / Structural Sections naturally and cross transfer material towards the end.

A rolling mill cooling bed is used for the uniform air cooling of the rolled materials (bars or profiles usually referred to as ‘bars’) and transport it in a phased manner from the entry side of the cooling bed to its discharge side. It transfers the bars one by one to the roller table, on which they are transported to the finishing section. The bed is provided with bar alignment.

We manufacture cooling beds ensuring constant standardization and high equipment quality. Every movement is used to straighten material.

1) Twin-Channel Bar Receiving Mechanism: We at Steefo Industries manufacture Twin Channels operated either by Hydraulic or by Electro-Mechanical Drive through DC Motors. The Flappers that we use are made from SG Iron Material, giving excellent wear resistance and long life.

2) 4-Channel Bar Receiving Mechanism (Pneumatic): This type of Bar Handling system is used for Rolling Mills with 2 Strand Billet Rolling.

3) Braking Slide/ Hydraulic Apron Type: This type of Bar Receiving mechanism is widely used for Merchant Mills producing both Sections and TMT Bar as well as Light Section Mill.

4) Rake Type Automatic Cooling Bed: Automatic rake type cooling beds are highly automated, ensuring transfer of material by one pitch for every rake movement.

These are supported with:

a. Run- In Roller Tables – having apron type diverters or twin channels as bar delivery systems.

b. Aligning Roller Table – for uniform alignment of bar ends.

c. Transfer out Device / Layer Transfer – For transferring bars after Alignment to Run Out Roller Table.

d. Run Out Roller Table: For Feeding the Bars to Cold Shear.

e. Chain-skid type Semi-Automatic Cooling Bed: Used For Heavy Sections such as Big Angles, Channel and I Beams.