The steel manufacturing industry heavily relies on rolling mills to convert raw materials into finished products in an accurate and efficient manner. In India, where the demand for high-quality steel products is continuously increasing, rolling mill manufacturers need to focus on improving their production efficiency. Hot rolling mill scheduling is a crucial aspect of this optimisation process, as it ensures smooth operations and maximizes output. This process is complex but vital and helps businesses achieve their goals for efficient and high-quality metal production.

Understanding Hot Rolling Mill Scheduling

Definition and Basics:

Hot rolling mill scheduling involves the systematic planning and organization of various production tasks within a mill facility. It encompasses the coordination of processes such as heating, rolling, and cooling to ensure a continuous flow of materials and efficient utilization of equipment. The scheduling process is essential for meeting production targets, maintaining product quality, and minimizing downtime.

The role of scheduling in managing production processes cannot be overstated. It acts as a bridge between the demand for finished products and the capabilities of the rolling mill. Scheduling involves creating a timeline that optimally sequences tasks, from preparing raw materials to the final product’s dispatch. Key terms and concepts in the scheduling include job sequencing, batch processing, lead times, and setup times.

Importance of Scheduling in Hot Rolling Mills

Effective scheduling is a cornerstone of overall production efficiency in rolling mills. A well-designed schedule ensures that each stage of the production process operates at its maximum potential, resulting in higher throughput and reduced idle time. Conversely, poor scheduling can lead to downtime, delays, and increased operational costs.

Consider a scenario where the scheduling of heating and rolling processes is not aligned. This misalignment can result in overheating or underheating of materials, leading to defective products and increased scrap rates. Moreover, inadequate scheduling may cause equipment to remain idle, reducing the mill’s overall efficiency and affecting the bottom line.

Challenges

The challenges associated with scheduling in hot rolling mills are multifaceted. These challenges include the dynamic nature of market demands, the variability in raw material quality, and the need to balance maintenance activities with production requirements. Addressing these challenges requires a strategic approach and a deep understanding of the factors influencing scheduling decisions.

Factors Affecting Hot Rolling Mill Scheduling

1. Raw Material Availability:

Raw materials are the lifeblood of any rolling mill, and their availability in quantity and quality is crucial for efficient scheduling. Schedulers must work closely with procurement teams to ensure a steady supply of raw materials. Additionally, implementing strategies for managing and optimizing raw material inventory, such as just-in-time delivery and effective storage solutions, can contribute to a smoother scheduling process.

2. Equipment Maintenance:

The significance of well-maintained machinery in hot rolling mill scheduling cannot be overstated. Regular preventive maintenance is essential to minimize unexpected breakdowns and downtime. Schedulers must collaborate with maintenance teams to develop maintenance schedules that align with production demands. Proactive measures, such as condition monitoring and predictive maintenance, can help anticipate potential equipment failures and plan maintenance activities accordingly.

3. Production Demand and Market Trends:

Adapting scheduling to meet varying production demands is a dynamic challenge faced by rolling mills. Schedulers must stay informed about market trends, customer orders, and industry forecasts to adjust production schedules accordingly. Flexibility in scheduling is essential to accommodate changes in demand, whether due to seasonal fluctuations or unexpected market shifts. Collaborating closely with sales and marketing teams ensures the production schedule aligns with customer requirements and market demands.

4. Data-Driven Scheduling:

In this digital age, data is an integral aspect of processes. For hot rolling mill scheduling, collecting and analyzing relevant data is a game-changer. Data-driven scheduling involves the systematic gathering of information from various stages of the production process, including raw material procurement, equipment performance, and product quality metrics.

By leveraging data, schedulers gain valuable insights into the historical performance of the rolling mill. This information enables them to identify patterns, predict potential bottlenecks, and make informed decisions to optimize the schedule. For example, analyzing the historical data on equipment downtime can lead to proactive maintenance planning, reducing the risk of unplanned stoppages.

Implementing data-driven decision-making in hot rolling mill scheduling involves the use of key performance indicators (KPIs) and analytics tools. KPIs, such as throughput rates, equipment utilization, and defect rates, provide a quantitative measure of the production process’s efficiency. Analytics tools can process vast amounts of data quickly, offering real-time visibility into the status of the mill and facilitating rapid decision-making.

The shift towards data-driven scheduling empowers rolling mill operators in India to move from reactive to proactive planning, ultimately reducing production costs and improving overall efficiency.

5. Advanced Scheduling Software:

Modern scheduling tools and software have revolutionized the way rolling mills plan and execute their production schedules. These advanced solutions go beyond traditional methods, offering real-time insights, optimisation algorithms, and automation capabilities.

Scheduling software tailored for hot rolling mills provides a centralized platform for managing all scheduling aspects. It allows schedulers to input various parameters, such as production targets, equipment capabilities, and maintenance schedules. The software then uses optimisation algorithms to generate an optimal production schedule that maximizes efficiency and minimizing downtime.

One of the notable benefits of using advanced scheduling software is the ability to make real-time adjustments. As market demands fluctuate or unexpected disruptions occur, the software can quickly recalculate the schedule, ensuring that the production plan remains aligned with the business objectives. This flexibility is crucial for rolling mill operators in India, where market dynamics can change rapidly.

Additionally, scheduling software enhances collaboration among different departments within the mill. By providing a transparent and accessible platform, it facilitates communication between production, maintenance, and quality control teams. This collaborative approach ensures that everyone is on the same page and can work together to address any challenges that may arise during the production process.

6. Collaboration and Communication:

Effective communication is a linchpin in successful hot rolling mill scheduling. The complex coordination of various tasks, from raw material preparation to the dispatch of finished products, requires seamless communication among different departments and teams.

Schedulers must collaborate closely with procurement teams to ensure a steady and reliable supply of raw materials. By sharing information about inventory levels, lead times, and material specifications, scheduling decisions can be made with a clear understanding of the available resources.

Furthermore, communication with maintenance teams is crucial to align preventive maintenance schedules with production requirements. By sharing insights into equipment performance and maintenance needs, schedulers can avoid unplanned downtime and ensure that machinery is in optimal condition during peak production times.

Commonly Asked Questions

1. How does data-driven scheduling benefit hot rolling mills?

Data-driven scheduling provides hot rolling mills with valuable insights derived from historical performance data. By analyzing key metrics such as throughput rates and equipment utilization, mills can make informed decisions, predict potential issues, and optimise their production schedules. This approach enables a shift from reactive to proactive planning, reducing downtime and improving overall efficiency.

2. What role do advanced scheduling tools play in optimizing production schedules for rolling mills?

Advanced scheduling tools revolutionize production planning for rolling mills by offering real-time insights, optimisation algorithms, and automation features. These tools enable schedulers to input various parameters and generate optimal production schedules. The real-time adjustment capabilities of these tools are particularly beneficial for adapting to fluctuating market demands, ensuring that mills can maintain flexibility in their production plans.

3. How can scheduling software enhance collaboration within rolling mill facilities?

Scheduling software facilitates collaboration by providing a centralized platform for managing production schedules. It enables transparent communication between departments, such as production, maintenance, and quality control. This collaborative approach ensures that all teams are aligned, making it easier to address challenges and make coordinated decisions during the production process.

4. Why is effective communication crucial for hot rolling mill scheduling?

Effective communication is vital for the complex coordination of tasks within hot rolling mills. Schedulers must collaborate closely with procurement teams to ensure a reliable supply of raw materials and communicate with maintenance teams to align preventive maintenance schedules with production requirements. Clear communication helps avoid unplanned downtime and ensures that equipment is well-maintained during peak production periods.

5. How can rolling mills adapt their schedules to varying production demands and market trends?

Rolling mills can adapt their schedules by staying informed about market trends, customer orders, and industry forecasts. This knowledge allows schedulers to adjust production schedules accordingly, ensuring that the mill can meet changing demands. Flexibility in scheduling is essential for accommodating seasonal fluctuations or unexpected shifts in the market, helping rolling mills maintain a competitive edge.

Consult Us for Custom Turnkey Solutions for Productive Rolling Mill Operations

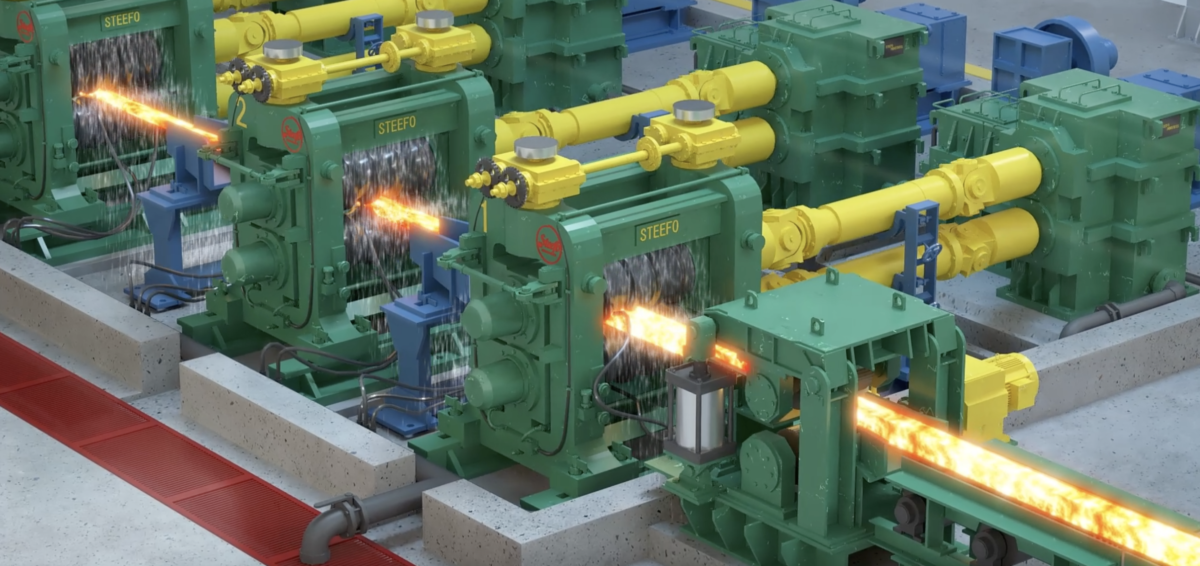

Unlock the potential of your rolling mill operations with our tailored turnkey solutions! At The Steefo Group, we specialize in delivering custom solutions designed to enhance the productivity and efficiency of your rolling mill. Our experienced team understands the unique challenges of the industry and is ready to collaborate with you to optimize every aspect of your production process.

Whether you’re seeking to improve scheduling, implement advanced technologies, or streamline communication across departments, our experts are here to guide you. Consult us for personalized insights and strategies that align with your specific goals and challenges. Together, let’s transform your mill into a powerhouse of efficiency. Elevate your operations, reduce costs, and stay ahead in the competitive landscape.

Contact us at +91 87589 98607 or email us at marketing@thesteefogroup.com for a consultation and take the first step towards achieving excellence in your rolling mill operations.