Rolling mills are the backbone of the metalworking industry, enabling the production of high-quality steel products for various applications. When setting up or expanding a mill, businesses must choose between turnkey solutions and traditional solutions to meet their project requirements. Each approach has its advantages, challenges, and suitability depending on factors like project scope, budget, and timeline.

This article explores the differences between turnkey and traditional solutions, helping steel plant operators and owners make an informed decision.

What Are Turnkey Solutions?

Core Characteristics

A turnkey solution is a comprehensive approach where a single provider takes responsibility for the entire rolling mill project, from design and engineering to installation and commissioning. The contractor delivers a fully operational facility, ready for immediate use. This model ensures seamless execution, minimising the need for multiple suppliers and contractors.

Components of a Turnkey Steel Rolling Mill Project

A turnkey project for steel plant typically includes:

- Engineering and Design: Detailed planning, feasibility studies, and process optimisation

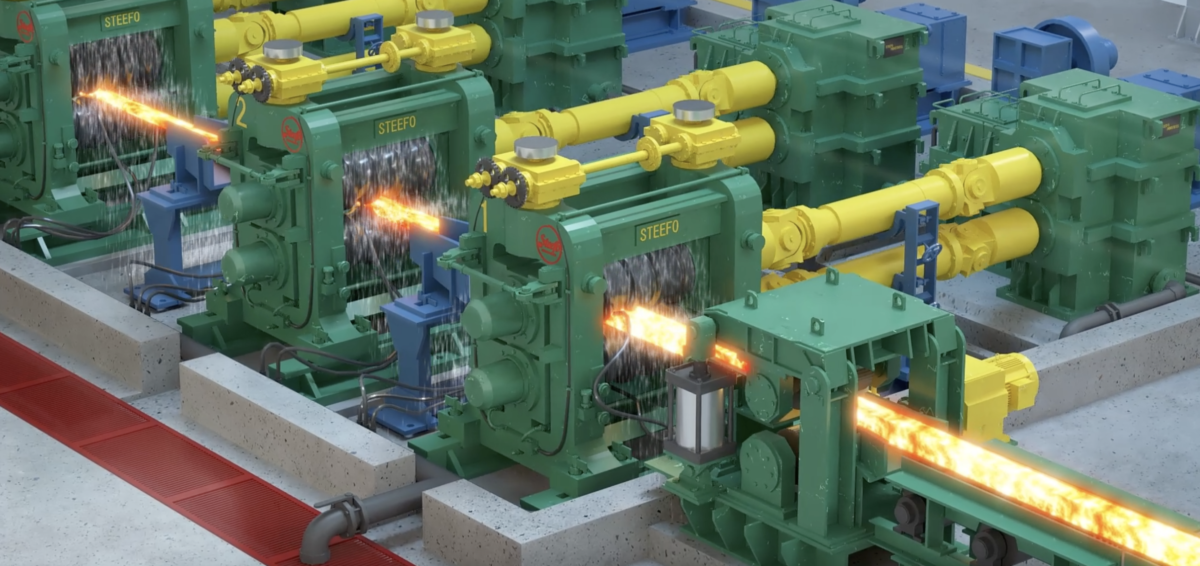

- Equipment Supply: Procurement of rolling mill machinery, automation systems, and auxiliary equipment

- Construction and Installation: Civil works, structural engineering, and mechanical installations

- Automation and Control Systems: Integration of digital technologies for efficient monitoring and operation

- Commissioning and Training: Testing the plant’s performance and training the workforce for smooth operation

Key Benefits of Turnkey Solutions

- Faster Implementation: With a single contractor handling the project, coordination is streamlined, reducing project timelines.

- Reduced Risk: A turnkey provider assumes responsibility for quality, performance, and compliance, minimising risks for the business.

- Single-Point Responsibility: Instead of dealing with multiple vendors, businesses have one contact for all project-related concerns, ensuring accountability.

- Cost Predictability: A turnkey approach typically comes with a fixed budget, helping businesses avoid cost overruns.

What Are Traditional Solutions?

Core Characteristics

A traditional solution involves businesses selecting and managing multiple suppliers, contractors, and service providers for different aspects of the rolling mill project. This approach allows for a high degree of customisation, enabling steel plant owners to tailor their steel mill according to specific requirements.

Customisation and Flexibility in Selecting Individual Suppliers and Contractors

With a traditional approach, businesses have the freedom to choose:

- Equipment suppliers based on price, quality, and technology preferences

- Construction and engineering firms with specialised expertise

- Automation and control system providers suited to operational needs

Key Benefits of Traditional Solutions

- Greater Control: Businesses can oversee every stage of the project, ensuring it meets their exact requirements.

- Adaptability: The flexibility to integrate advanced or specialised technologies from different suppliers.

- Cost Distribution: Investments can be spread over time, helping manage cash flow efficiently.

- Scalability: Ideal for phased expansions, allowing businesses to grow their steel plant progressively.

Key Factors to Consider When Choosing Between Traditional and Turnkey Solutions

Project Scope and Complexity

Suitability of Turnkey Solutions for Large-Scale, End-to-End Projects:

- If a company requires a complete rolling mill setup with minimal involvement in the execution process, a turnkey solution is ideal.

- It ensures all components are designed to work together, reducing integration challenges.

When Traditional Solutions Work Better for Phased Expansions:

- For businesses planning incremental growth or specific machinery upgrades, a traditional approach provides more flexibility.

- If an existing steel plant is undergoing modernisation, selecting individual components from different vendors allows better customisation.

Budget and Financial Considerations

Turnkey Solutions: Predictable Costs with Upfront Investment

- Turnkey projects involve a higher upfront investment as they cover design, procurement, installation, and commissioning under a single contract. This consolidated approach simplifies budgeting and financial planning.

- With a fixed-price structure, turnkey solutions minimise the risk of cost overruns, ensuring that businesses stay within their planned budget.

Traditional Solutions: Flexible Spending with Potential Risks

- Traditional solutions allow businesses to spread costs over time by purchasing equipment and services in stages, making them more suitable for companies with limited capital.

- However, this fragmented approach can lead to higher overall costs due to unforeseen coordination issues, project delays, and discrepancies between multiple suppliers, increasing the risk of budget overruns.

Timeline and Project Delivery Speed

- Since all aspects are handled by a single contractor, project completion is more streamlined, minimising downtime.

- Ideal for businesses that need to start operations quickly.

Traditional Solutions Offer More Flexibility But Require Careful Planning:

- The phased approach in traditional solutions may extend project timelines due to separate procurement, installation, and testing processes.

- Coordination between multiple suppliers and contractors may lead to unexpected delays.

Quality Assurance and Performance Optimisation

Turnkey Solutions Guarantee Standardised Quality

- A single vendor ensures that all components of the rolling mill are integrated efficiently, avoiding compatibility issues.

- Automation and control systems are optimised for performance and reliability.

Traditional Solutions Provide Customisation but Require Rigorous Quality Control

- Businesses can select specialised equipment for better customisation but must ensure proper compatibility between different components.

- Requires experienced project managers to maintain consistency and performance.

Vendor Management and Accountability

Turnkey Solutions Simplify Vendor Management

- One contractor assumes full responsibility, ensuring smooth communication and accountability.

- Reduces complexity in coordinating multiple contracts.

Traditional Solutions Require Active Vendor Coordination

- Businesses must manage multiple contracts, ensuring clear communication between suppliers and contractors.

- Potential risk of misalignment between different service providers.

Frequently Asked Questions

1. How do turnkey solutions improve project timelines compared to traditional approaches?

Turnkey solutions streamline project execution by consolidating all aspects—design, procurement, construction, and commissioning—under a single contractor. This eliminates the inefficiencies caused by multiple vendors, reducing lead times and ensuring a faster setup of a rolling mill. Traditional approaches, on the other hand, often face delays due to staggered procurement, extended approval processes, and coordination challenges among multiple contractors.

2. What are the key cost differences between turnkey and traditional steel rolling mill setups?

Turnkey solutions typically involve a higher initial investment but come with fixed pricing, reducing the risk of budget overruns. Traditional solutions may appear cost-effective at first but can lead to unforeseen expenses due to fragmented project management, contract negotiations, and vendor-related inefficiencies.

3. How does vendor management differ in turnkey vs. traditional steel rolling mill projects?

In a turnkey model, businesses deal with a single contractor responsible for delivering the entire project, simplifying communication and accountability. Traditional solutions require managing multiple suppliers and contracts, increasing the complexity of coordination and risk of inconsistencies.

4. Which approach—turnkey or traditional—is better for upgrading an existing steel rolling mill?

For a full-scale modernisation, turnkey solutions offer a seamless transition with minimal disruptions. However, if a business plans phased upgrades, a traditional approach allows greater flexibility to selectively replace or upgrade components over time.

5. How do turnkey solutions impact the long-term maintenance and operational efficiency of a steel plant?

Turnkey solutions provide integrated automation, optimised workflows, and standardised quality control, ensuring long-term efficiency. They often include post-installation support, training, and maintenance services, helping businesses sustain smooth operations with minimal downtime.

Partner with Us for the Right Steel Rolling Mill Solution

Choosing between a turnkey or traditional approach is a critical decision for your steel plant’s future. With our expertise in providing cutting-edge rolling mill solutions, we ensure seamless execution, high efficiency, and long-term success. Our turnkey solutions offer hassle-free project management, optimised production, and superior quality, while our customised traditional solutions give you full control over your project’s execution.

Let us help you design, build, and optimise a rolling mill that meets your exact needs. Contact us at +91 87589 98607 or email us at marketing@thesteefogroup.com to discuss your project and discover how we can bring value to your steel plant operations!